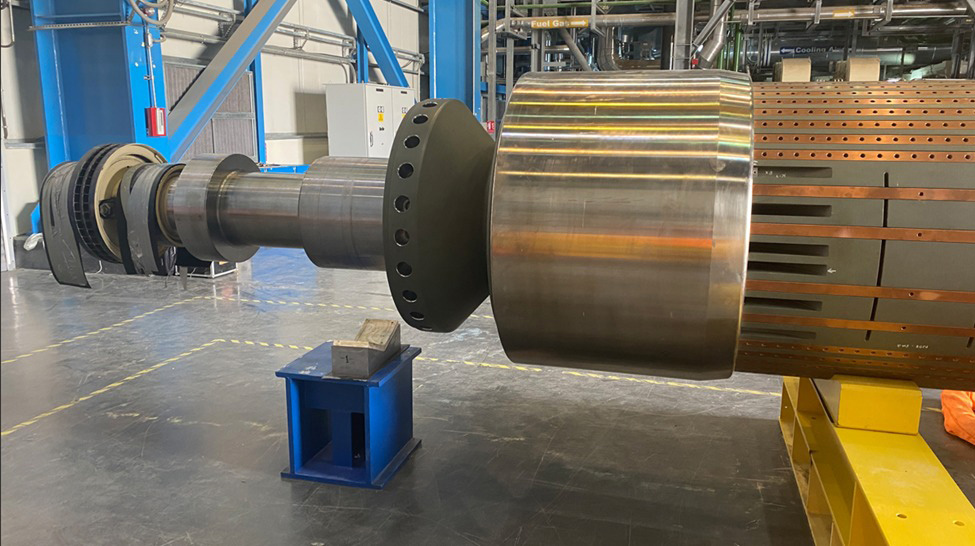

Rotor Kraft Türkiye, with its knowledge on generator equipment maintenance and repair It provides fast and effective service to our customers in power plants and public utilities across the country.

Additionally, we are determined to serve the energy production sector without compromising on safety and quality.

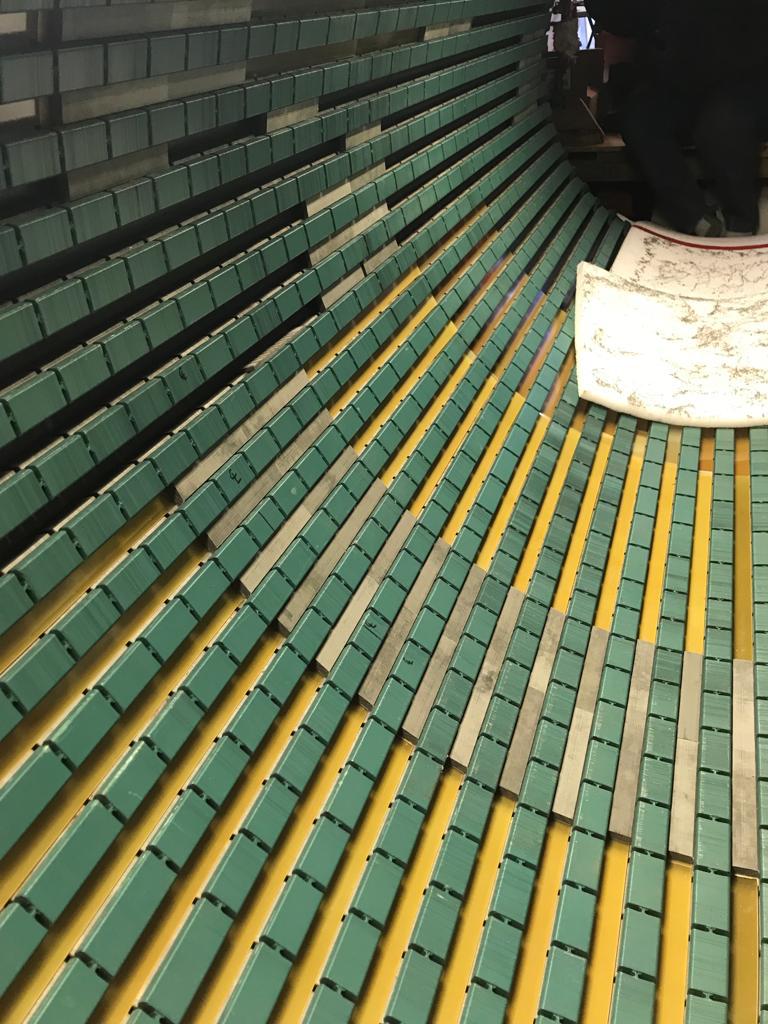

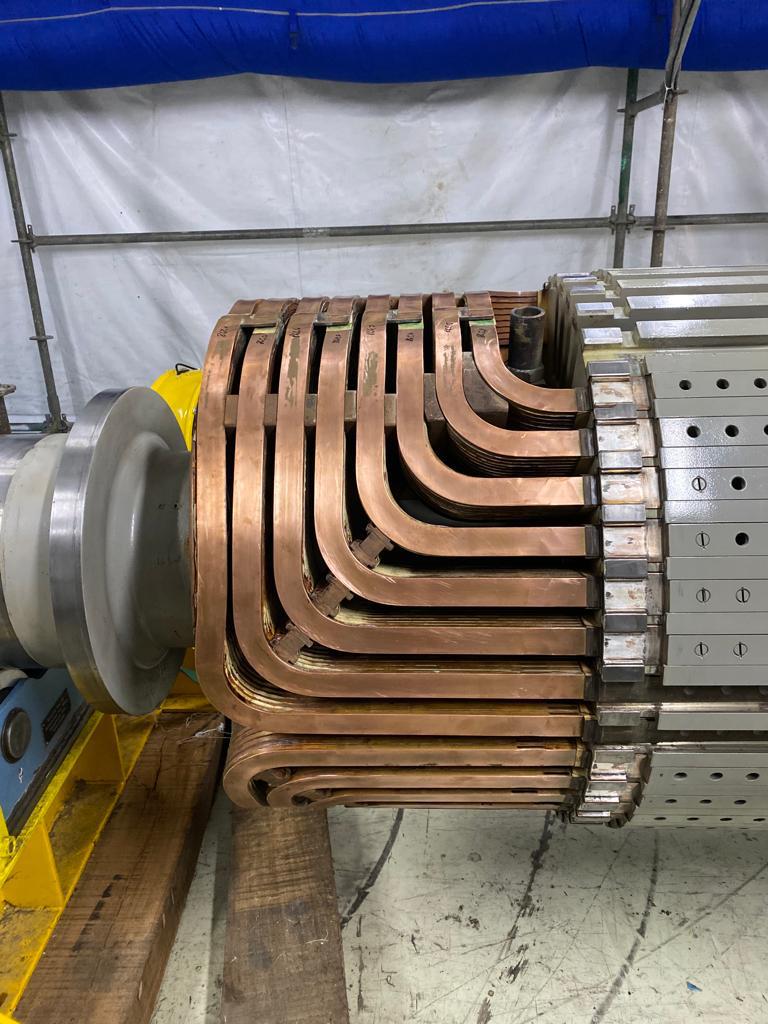

Rotor Kraft Türkiye, offers the highest quality maintenance or repair service for your generator equipment by developing work packages specific to each project.

Our goal is to support and lead our customers in identifying their maintenance needs. We provide service excellence with a corporate touch by developing and implementing maintenance solutions that enhance the plants of our clientele.

We strive as a company to provide high quality and value-added complete repair and maintenance solutions.

Integrity, Innovation, Reliability, Respect, Empowerment, Staff Diversity, Teamwork, Dedication, Commitment, Customer Satisfaction

Business Start

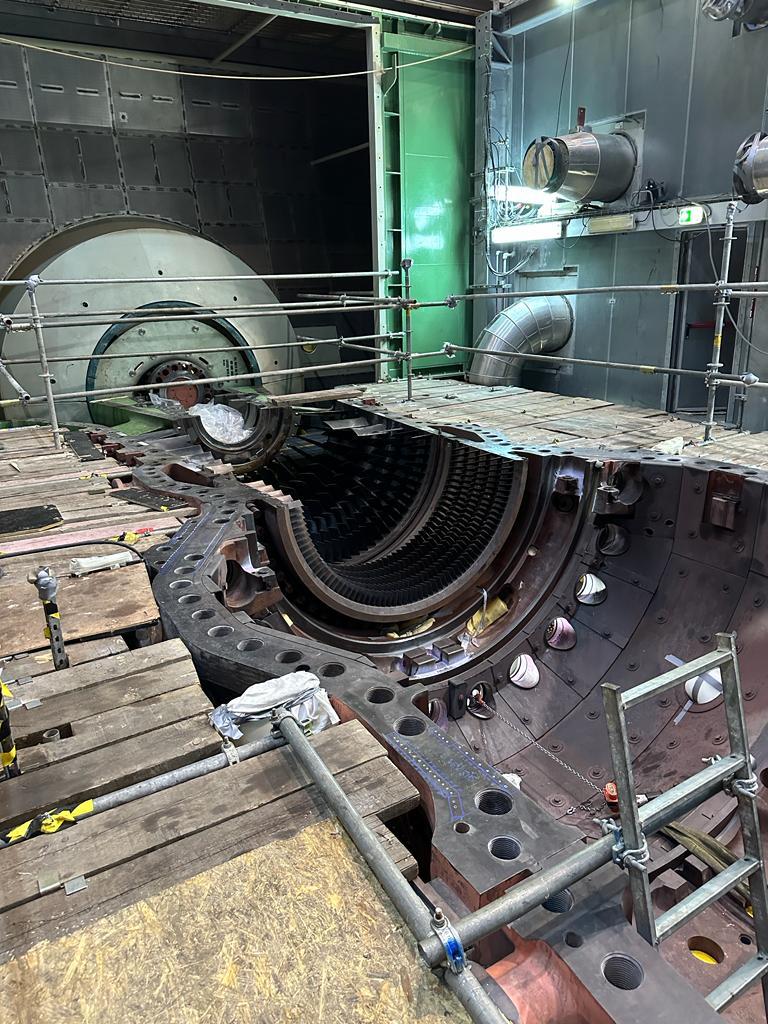

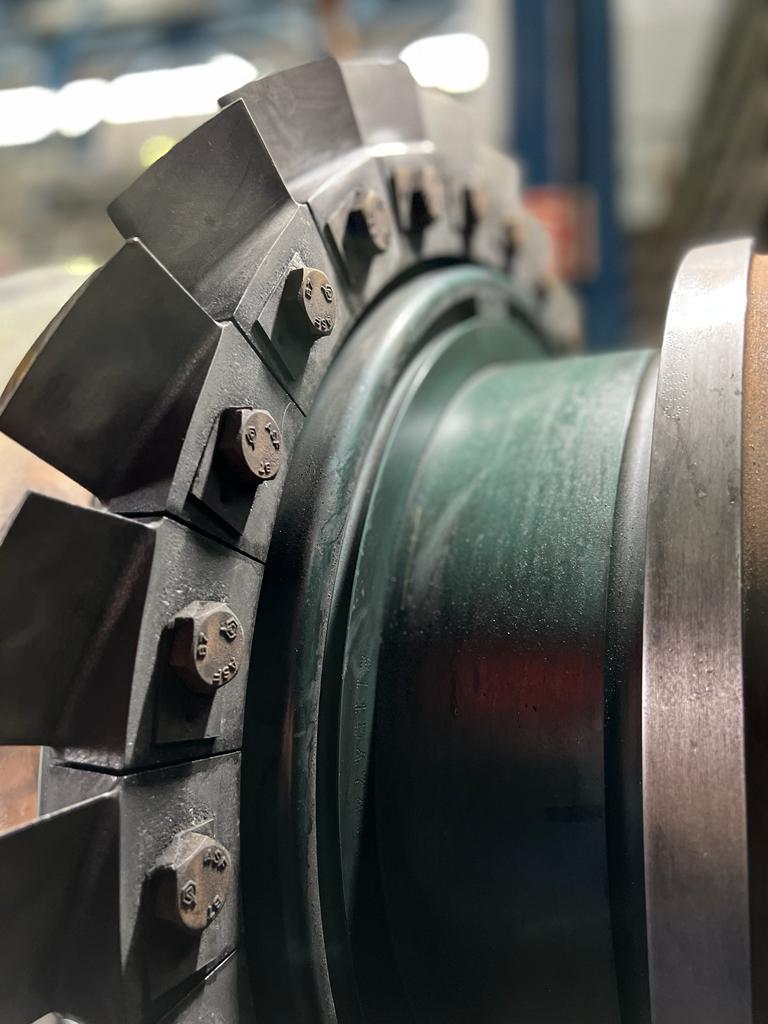

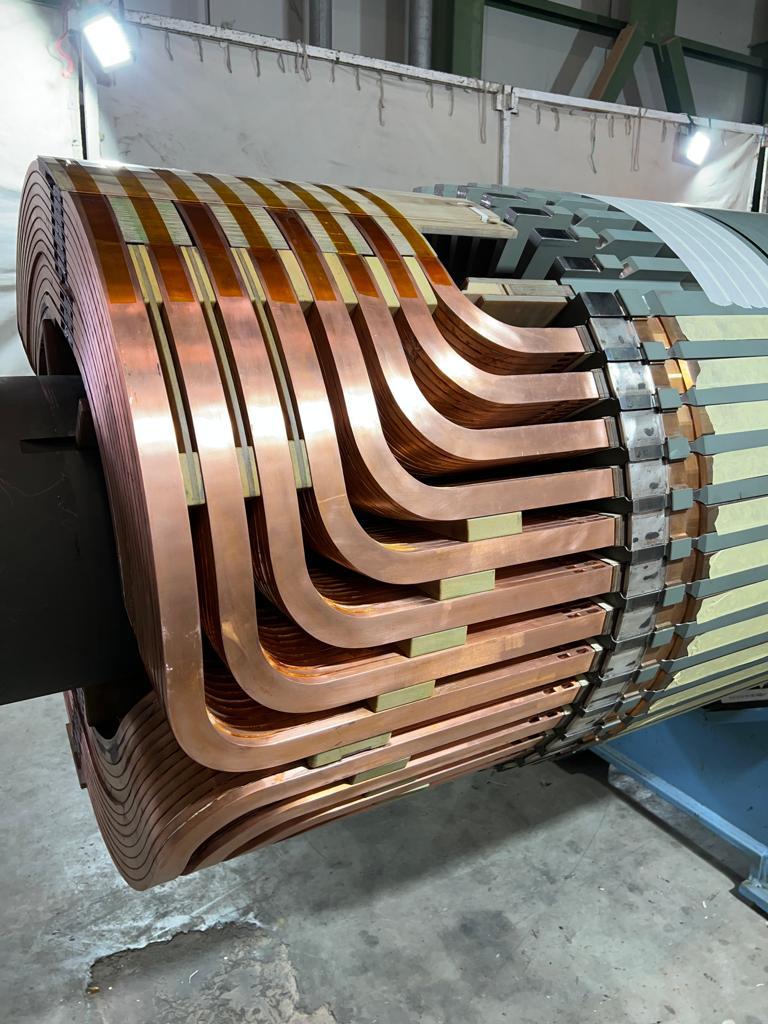

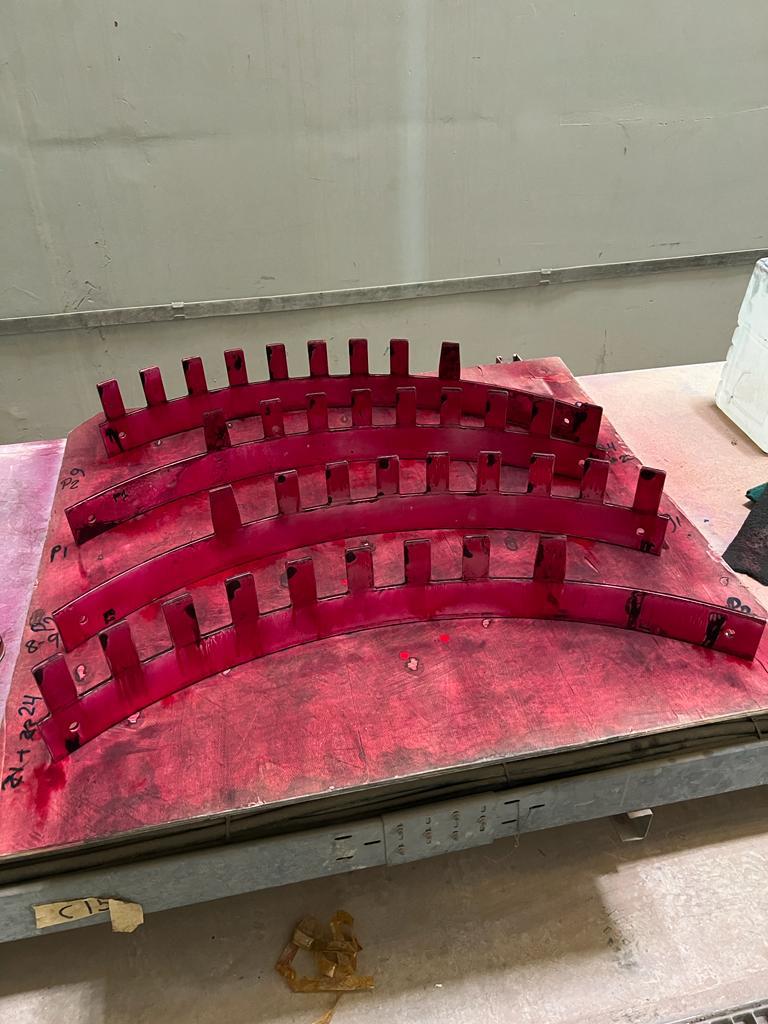

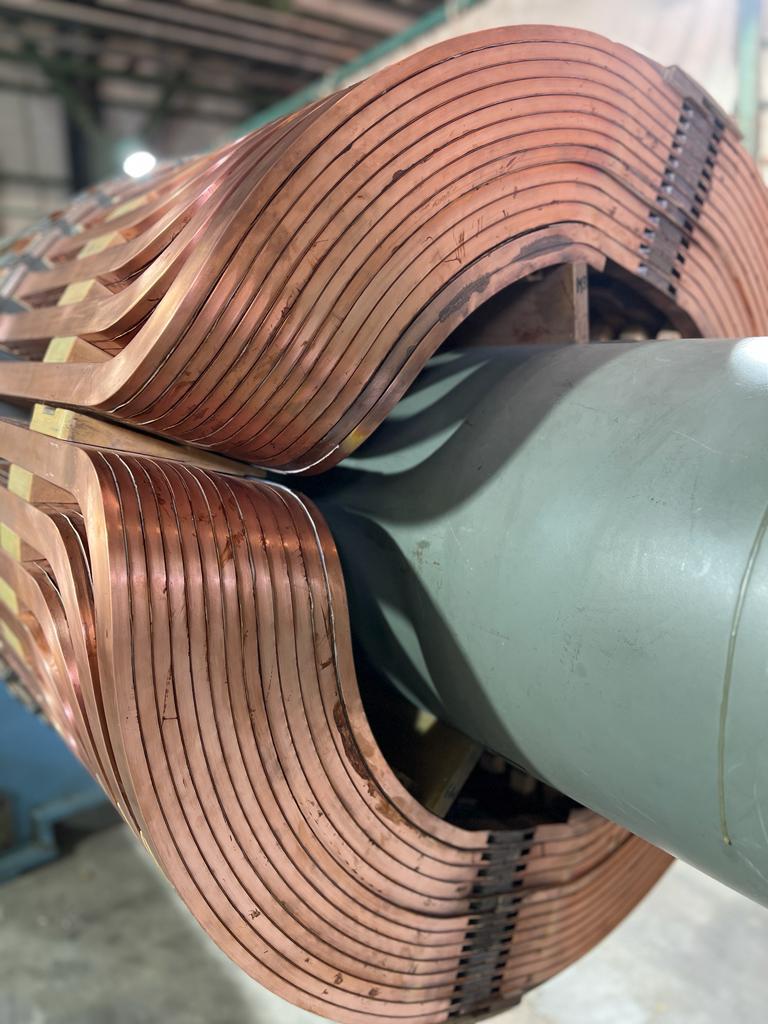

Starting to provide technical support for GE, Alstom and Siemens generators maintenance & repair projects

Completion of the first full generator maintenance & repair project

15 generator maintenance projects were completed in Canada, Algeria, Argentina, Colombia, El Salvador, Mexico and Peru

Completion of the first generator maintenance & repair project in Türkiye

Rotor Kraft Türkiye

has been officially registered

15+ years combined specialist experience in the

Rotor Services division

Staff average 10+ years’ experience

Trained and experienced personnel provide high quality service

Efficient and certified operational processes

Our Rotor Services division has completed over

25 projects since 2008

Loyal customers include General Electric

Highly competitive rates

On-time and on-budget performance

Team members are committed to the success

and future of the company

We generates services with the optimum amount of time and money needed to produce them

We are accountable and consistently performing and delivering on what we promise

We take all actions in the present that binds us to our future responsibilities

Rotor Kraft Enerji San. ve Tic. A.Ş.

Location

Location

Ünalan Mahallesi Libadiye Caddesi Emaar Residence No: 82 E Blok Daire: 291 34700 Üsküdar İstanbul TÜRKİYE

Call Us

Call Us

+90 216 606 6175

E-Mail

E-Mail

info@rotorkraft.com.tr

We use cookies to make sure that our website works properly, as well as some optional cookies to personalise content and advertising, provide social media features and analyse how people use our site. By accepting some or all optional cookies you give consent to the processing of your personal data, including transfer to third parties, some in countries outside of the European Economic Area that do not offer the same data protection standards as the country where you live. You can decide which optional cookies to accept by clicking on "Manage preferences", where you can also find more information about how your personal data is processed. Further information can be found in our privacy policy.